Crafting Tomorrow’s Legacy in Glass

From fire-rated to specialty mirror and architectural glass fabrication, Torstenson Glass has been committed to excellence for over 130 years.

137

Years in Business

150

Stocked Glass Products

175

Years of Combined Employee Sales Experience

22

Years FireLite Distribution

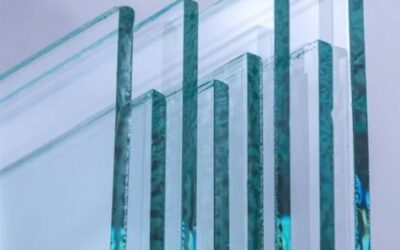

Our Products

We stock over 150 types of glass products in a variety of glass categories. If you don’t see something, just ask!

Fire-Rated Glass

Flat Glass

Mirrors

Patterned/Textured Glass

Bullet Resistant Glass

Bird Safe Glass

Specialty Systems

Torstenson Glass has partnered with specialty manufacturers to add high end glazing systems to our offering. Select a product to learn more.

Bullet Resistant Assemblies

Pass-Thru Awning Window

Industries Served

Torstenson Glass offers a range of specialized glass products, tailored to meet the unique needs in every application.

Glass Installers & Fabricators

We provide a wide range of top-quality glass products, including custom-cut and pre-treated options, ensuring swift installation and enhancing your reputation for excellence and precision in every project.

Door, Cabinet, & Window

Elevate your window and door creations with Torstenson Glass including standard doors, hollow metal doors, garage doors, kitchen cabinet doors, and more.

Millwork

Quality glass solutions for corporate, medical, and hospitality environments, point of purchase and store display products, furniture and more.

OEM Equipment

We source and fabricate precision glass components tailored to meet the exacting standards of the most rigorous certifications, including the testing equipment industry.

SERVICES

Fabrication & Delivery Services

From beveling and polishing to radiused corners and custom cutouts, our in-house fabrication capabilities are set up to provide the customization needed for complex glass projects. We deliver glass in the greater Chicagoland area and can ship glass anywhere in the U.S.

The Torstenson Difference

Innovation and Quality

In an industry where many compromise quality for speed, Torstenson stands firm. We merge tradition with modern innovation, ensuring you receive top-quality products with every purchase.

Versatility and Range

While others offer one-size-fits-all solutions, our diverse portfolio features fire-rated glass, specialty mirrors, and architectural fabrications. We cater to every unique requirement, from individual pieces to expansive custom projects.

Expertise and Inventory

Many suppliers may lack the depth of industry knowledge, but not Torstenson. With a vast inventory ready to meet diverse needs, our sales team’s unparalleled 175 years of expertise ensures efficient service and informed product selection.

Largest TGP Fire-rated Glass Distributor

Sourcing reliable fire-rated glass can be challenging. As the largest distributor of Technical Glass Products FireLite glass in the U.S., we guarantee quality and safety with the #1 specified brand in the U.S.

Our Reviews

Experience the TG Difference

Discover the TG difference, where quality meets exceptional customer service.

Trust in our expertise, vast inventory, and exclusive offerings. Let us exceed your expectations today. Ready for excellence?